Table of Contents

Continuous rapid growth of AI (Artificial Intelligence) in every sector has transformed the technology in a better way, and the manufacturing industry is no exception. Today, Artificial Intelligence is a highly impactful technology changing the game of AI in manufacturing. Currently, AI in manufacturing is driving efficiency, reducing costs, and helping make smarter production decisions.

In this blog, we will see in depth about AI in Manufacturing, how it is reshaping the industry and what its future holds. Furthermore, we will also look at real-world AI in manufacturing examples to understand its practical benefits.

What is AI in Manufacturing?

AI in manufacturing refers to the applications of AI technologies, in which include machine learning machine learning, computer vision and also predictive analytics to automate and improve manufacturing processes. It optimizes machines and systems to analyze the data, learn from it and proceed intelligent decisions without human interference.

Whether it’s improving quality control or reducing machine downtime, AI in manufacturing is making factories smarter and greater responsive to change.

Why is AI in Manufacturing Important?

AI in Manufacturing is very important, because the manufacturing sector faces lots of challenges like rising costs, global competition, shortages of labour and many more. Traditional systems struggle to manage with these modern demands. That’s where AI in manufacturing steps to fulfil these demands.

By using intelligent algorithms and data-driven systems, manufacturers can:

- Predict equipment failures before they happen

- Improve product quality and reduce waste

- Optimize production schedules

- Automate repetitive tasks

- Enhance worker safety

These benefits make AI in Manufacturing a vital tool for companies aiming to stay competitive and efficient.

The Role of AI in Industry

The role of AI in industry is increasing very quickly. Industrial operations produce massive volumes of data, and Artificial Intelligence helps this data to sense in real time. From logistics to maintenance, AI in industry is completely helping the leaders to make quick and better decisions.

In the industrial world, AI can:

- Monitor equipment through sensors and predict when it needs maintenance

- Analyze demand and adjust production accordingly

- Identify defects in real-time using computer vision

- Reduce energy consumption through intelligent systems

The integration of AI in industry is not only regards for automation- it’s about creating smart ecosystems that adapt to the work and evolve.

Applications of AI in Manufacturing

Let’s go through some of the most common applications of AI in Manufacturing:

- Predictive Maintenance

Machines can break down or be damaged without warning, leading to costly maintenance. With AI in Manufacturing, predictive maintenance uses advanced sensors and machine learning to predict breakdowns and schedule timely repairs. This helps to reduce maintenance costs.

- Quality Control

Computer vision, which are powered by AI, analyzes the products faster and more accurately than humans. It can detect even the smallest defects during the production process, which helps industries to maintain their quality standards.

- Supply Chain Optimization

Artificial Intelligence identifies supplier data, logistics and inventory levels to suggest better and quality decisions for material procurement and stock management. This definitely helps manufacturers avoid delays and shortages.

- Robotics and Automation

AI-driven advanced robots are used in assembly and production lines for automation tasks like welding, painting, and packaging the product. These robots learn through machine learning and perform the tasks more efficiently over time.

- Process Optimization

AI analyzes the data from the production line to identify inefficiencies. After than, it suggests changes to improve workflow, save energy or speed up production.

Each of these applications contributes to the overall goal of making AI in Manufacturing more efficient and future-ready.

AI in Production: A Smarter Way to Manufacture

AI in production is actually about integrating AI technologies into every corner or stages of the manufacturing process. From raw material planning to delivery, AI in production makes companies more accurate and efficient.

For example, imagine a factory floor where machines communicate with each other about analyzing performance in real time, and adapt to minimize delays. That’s the power of Artificial Intelligence in the sector of production.

Benefits of AI in Manufacturing

Here are some key benefits of adopting AI in Manufacturing:

- Cost Reduction

By automating the tasks and advanced prediction of future issues, manufacturers can save significantly on labour and maintenance costs.

- Increased Productivity

AI systems work 24/7 without fatigue. They complete tasks faster and more accurately, increasing output.

- Improved Safety

AI-powered robots and sensors can handle dangerous tasks, which helps to reduce the risk of accidents and ensures safety.

- Better Decision-Making

AI provides real-time data insights, which enables manufacturers to make faster and smarter decisions.

- Customization

AI can adjust production lines quickly to create customized products without slowing down the entire process.

AI in Industry: Changing the Workforce

While AI in industry automates many tasks, it also creates new opportunities for workers. Only workers needed to manage the program and maintain the AI systems. This shift in Artificial Intelligence requires new skills in data analysis, robotics and AI engineering.

Today, companies are investing in training programs to upskill their employees. As AI in industry continues to grow, the demand for tech-savvy workers will increase.

Real-World AI in Manufacturing Examples

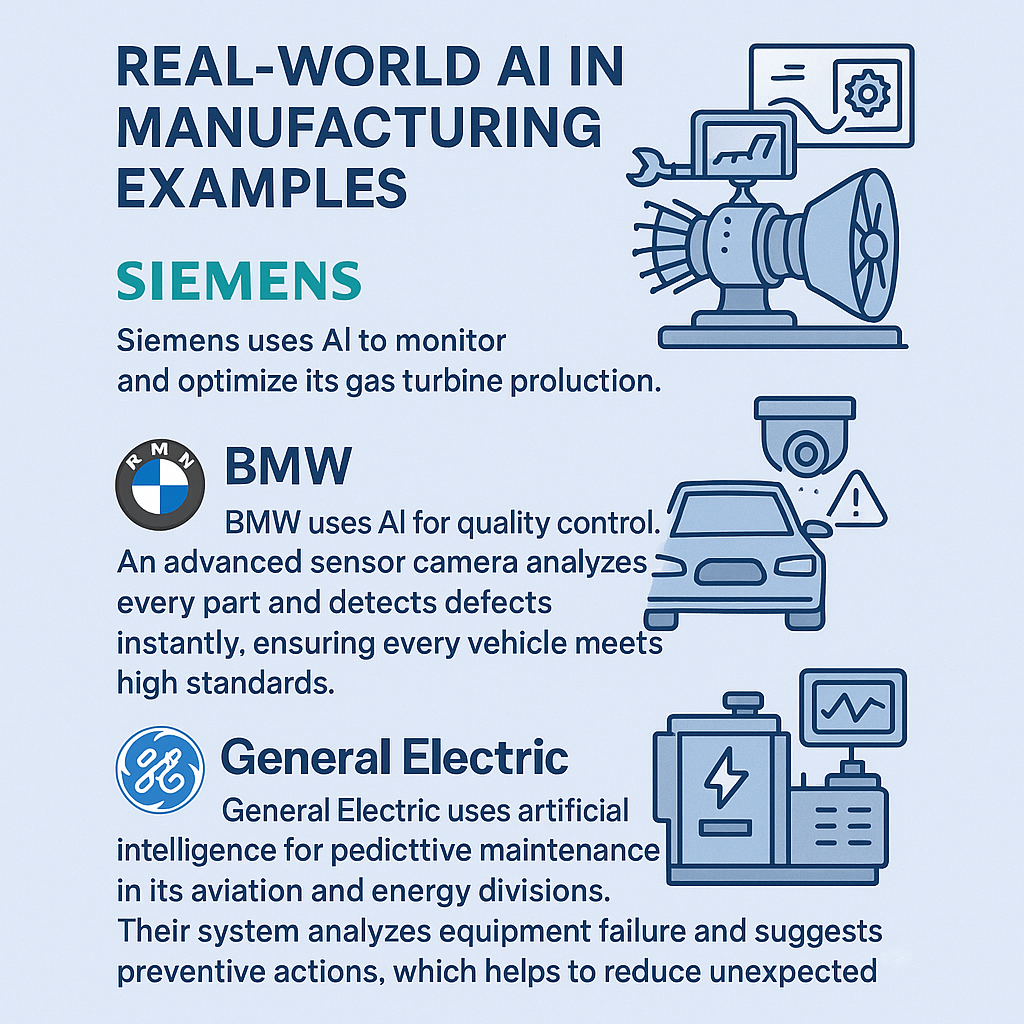

Let’s check some examples of AI in Manufacturing from global companies:

- Siemens

Siemens, a well-known company, uses AI to monitor and optimize its gas turbine production. Siemens, the famous and well-known company, uses AI to monitor and optimize its gas turbine production.

- BMW

BMW uses AI for quality control. An advanced sensor camera analyzes every part and detects defects instantly, ensuring every vehicle meets high standards.

- General Electric (GE)

General Electric uses Artificial Intelligence for predictive maintenance in its aviation and energy divisions. Their system analyzes equipment failure and suggests preventive actions, which helps to reduce unexpected downtime.

These AI in Manufacturing examples show how big companies are leveraging AI to transform operations and gain a competitive edge.

Challenges of Implementing AI in Manufacturing

Despite the benefits, implementing AI in Manufacturing does come with challenges:

- High Starting Investment

AI systems can be expensive to install and require advanced infrastructure. AI systems can be expensive to install, as it require advanced infrastructure.

- Data Privacy and Security

Manufacturers must always ensure that collected data, which is analyzed by AI, is secure from breaches or misuse.

- Workforce Resistance

Employees may be hesitant or fearful of new AI systems. Training and communication are essential to manage these transitions.

- Skill Gap

There is a shortage of professionals skilled in AI, machine learning, and data analytics, making it difficult for companies to implement AI effectively.

Overcoming these challenges is crucial for fully leveraging the power of AI in Manufacturing.

The Future of AI in Manufacturing

The future of AI in Manufacturing looks promising. As AI Advanced technology becomes more affordable and easily accessible, even small and medium-sized businesses will adopt it.

Upcoming trends include:

Edge AI: Processing data directly on devices rather than sending it to the cloud.

Digital Twins: Creating virtual replicas of machines to test and improve processes.

Collaborative Robots (Cobots): AI-driven robots working alongside humans.

With these advancements, the role of AI in industry will only expand, helping businesses stay resilient, responsive, and competitive.

Conclusion

AI in Manufacturing is creating a new era of how products are made, improving every step of the process, from the raw material to delivery. Whether it’s reducing downtime through predictive maintenance with computer vision, the impact is very clear and powerful.

As more companies adopt AI in production, we can expect smarter factories, better products, and a more skilled workforce. Real-world AI in Manufacturing examples prove that this isn’t science fiction—it’s happening right now.

The integration of AI in industry is no longer optional. It’s the key to staying ahead in an increasingly digital and fast-paced world. If you like this blog, Read AI related latest blog only at AiOnlineMoney.